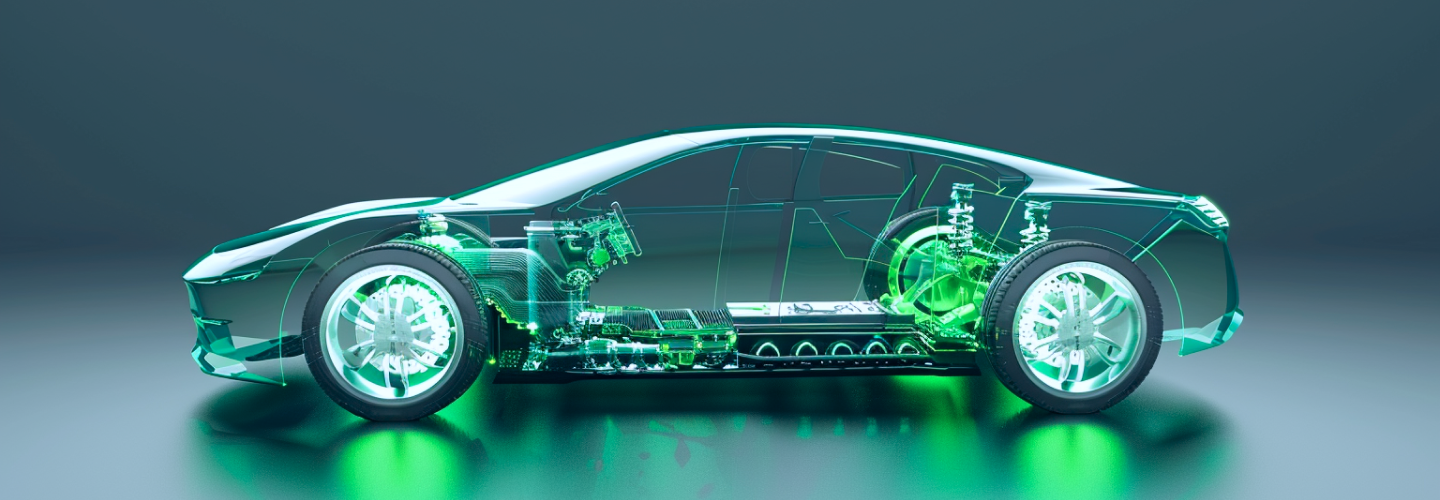

Automobiles are complex industrial products composed of numerous components and assemblies, and the working temperature and material tolerance temperature of each component are not the same. Only by ensuring that they operate at a suitable temperature can the safe, efficient, and stable operation of automobiles be guaranteed. The automotive thermal management system, on the other hand, takes into account both the system and the entire vehicle to coordinate and regulate the heat generated by the vehicle and the environment, ensuring that all components operate within the optimal temperature range.

Traditional automotive thermal management mainly includes engine and gearbox cooling, as well as air conditioning system thermal management.

The thermal management of new energy vehicles includes motor and electronic control system thermal management, battery system thermal management, and passenger cabin air conditioning thermal management.

Ⅰ. The range of electric vehicles deteriorates in winter. The activity of winter batteries decreases, which in turn affects battery performance. All heating requires a new heating source to solve, and this part of the heat comes from the power battery, which naturally affects the battery life. In winter, the viscosity of lubricating grease in the transmission system increases, leading to an increase in transmission resistance.

Ⅱ. Charging time is too long. Charging time for electric vehicles is too long at low temperatures.

Ⅲ. Hidden door handle malfunction. The problem of hidden door handles not being able to pop out or retract.

Ⅳ. Car door malfunction, abnormal glass lifting. The driver's glass was damaged due to compression with the door frame when closing the door. The door frame has water, causing the door frame to freeze after opening the door, and the self-priming door cannot be closed properly. The driver's door cannot be opened or closed from the outside, which may result in the vehicle not being able to travel normally or the safety during driving cannot be guaranteed.

Ⅴ. The air conditioner cannot heat up. During the testing process, the vehicle's air conditioner did not heat up and blew cold air, causing problems with the manufacturer's vehicle heat pump. Poor heating effect. In pure electric mode, turning on the air conditioning for heating will activate the vehicle's range extender.

Ⅵ. Power failure and brake failure, intermittent power interruption phenomenon, will disappear after the car heats up. After the 24-hour freezing test, it is not possible to shift into P and D gears. There is a problem with the braking system.

2、 Summer Pain Points

Ⅰ. High risk of spontaneous combustion. Batteries may experience high-temperature spontaneous combustion when exposed to direct sunlight.

Ⅱ. Insufficient power. Battery overheating, limited discharge rate, and restricted power. The motor temperature is too high.

Ⅲ. The range has decreased. The air conditioning needs to be turned on, so the range will be lower than normal.

Ⅳ. Extended charging time. In summer, the ambient temperature is high, and the heat generated by the power battery cannot be quickly dissipated, resulting in high battery temperature during charging and prolonged charging time.

Ⅴ. The air conditioner does not cool or has poor cooling effect. When the cooling capacity is insufficient, priority should be given to ensuring battery cooling. Refrigeration system high pressure alarm protection shutdown.

The typical usable temperature range for ternary lithium-ion batteries used in electric vehicles is -30 ℃~55 ℃, but the only range that can truly achieve the highest charging and discharging performance is the narrow range of 25 ℃~45 ℃.

At present, most battery management systems control the battery temperature not to exceed 60 ℃. This is because many materials and active substances inside the battery are easily decomposed at high temperatures. Once decomposed, the reaction will accelerate, and it will basically develop into a fire that cannot be recovered, which is commonly known as "thermal runaway".

1.The difference between gasoline powered cars and electric cars

Under the trend of electrification, the thermal management system of the entire vehicle has undergone significant changes. New energy vehicles without heat engines require additional heat generation devices to maintain the efficient operation of the entire system. The high temperature sensitivity of batteries also increases the complexity and refinement requirements for thermal management of new energy vehicles. There are still significant differences between the thermal management systems of new energy vehicles and fuel vehicles.

Ⅰ. Traditional cars use engine lung heat to heat the passenger compartment, while new energy vehicles require heating devices to generate heat.

Traditional internal combustion engine vehicles utilize the waste heat generated by the engine, which is adjusted to a suitable temperature through a warm air core and blown into the cockpit by a blower to heat the passenger compartment.

Due to the lack of heat generated by internal combustion engines, new energy vehicles can only obtain additional heat from outside the system through additional PTC resistors or heat pump air conditioning to heat the passenger compartment.

Ⅱ. Traditional automotive power system thermal management mainly relies on cooling, and the power battery needs to be cooled and heated.

Traditional internal combustion engine vehicles generate a large amount of waste heat after high-speed operation, which needs to be promptly discharged to ensure efficient and stable operation of the mechanism. Therefore, traditional automotive power systems mainly focus on heat dissipation.

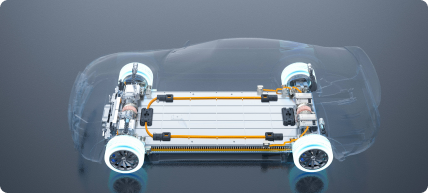

The performance of new energy vehicle power batteries is sensitive to temperature, and the battery performance is optimal at 15 ℃~35 ℃. Therefore, the power battery thermal management system needs to constantly control the battery temperature within a suitable temperature range to maximize battery performance.

Compared to gasoline vehicles, the thermal management system components of new energy vehicles are more numerous and more complex. The main changes can be summarized as follows:

Change 1: Diversification of components, addition of various electrical components such as electric compressors, PTC heaters, electromagnetic expansion valves, battery water-cooled plates, electromagnetic directional valves, etc.

Change 2: The system becomes more complex, and the layout of thermal management increases. PTC heating and heat pump systems are derived from heating, while the three electric heating management system is a pure new system that needs to cover the entire chassis.

Change 3: Fine temperature control, higher requirements for software and hardware. Compared to the engine, the three electric system is more sensitive to temperature. At the hardware level, a large number of P/T sensors need to be deployed; At the software level, there is a need to increase the pursuit of segmented scenarios and intelligent modes.

-

- Suyan Electronics completes a million dollar angel round financing to accelerate the research and development of thermal management technology for new energy vehicles

- 2024-09-09

-

- 2023 New Energy Vehicle Thermal Management Industry Report

- 2024-08-05

-

- What is automotive thermal management?

- 2024-08-05

-

- Thermal management technology for new energy vehicles

- 2024-08-05